|

Model |

ZX8-200R Large size bag feeding packaging machine |

|

Technical Highlights |

10-60 packs/min Advanced transmission mechanism to ensure stable operation/ Strong compatibility of size and specification, stable heat-sealing structure/excellent sealing quality |

|

Functions and Features |

Suitable for large-sized packaging bags, automatic metering, filling and sealing. The advanced bag-loading mechanism ensures a very high bag-loading rate. The advanced design concept ensures the stability of equipment operation, reduces the defective rate and prolongs the life of equipment operation Using high-quality accessories, the packaging machine is durable and stable. This machine uses prefabricated packaging bags with perfect packaging patterns and good sealing quality, thus improving the quality and grade of products. Adopt advanced PLC plus POD electrical control system, friendly man-machine interface, easy to operate. |

|

Main Standard Components |

1. Bag loading system 2. PLC control system 3. Bag opening device 4. Unloading system 5. Heat sealing control system 6. Output system 7. Cleaning system 8. Transfer system |

|

Scope of Application |

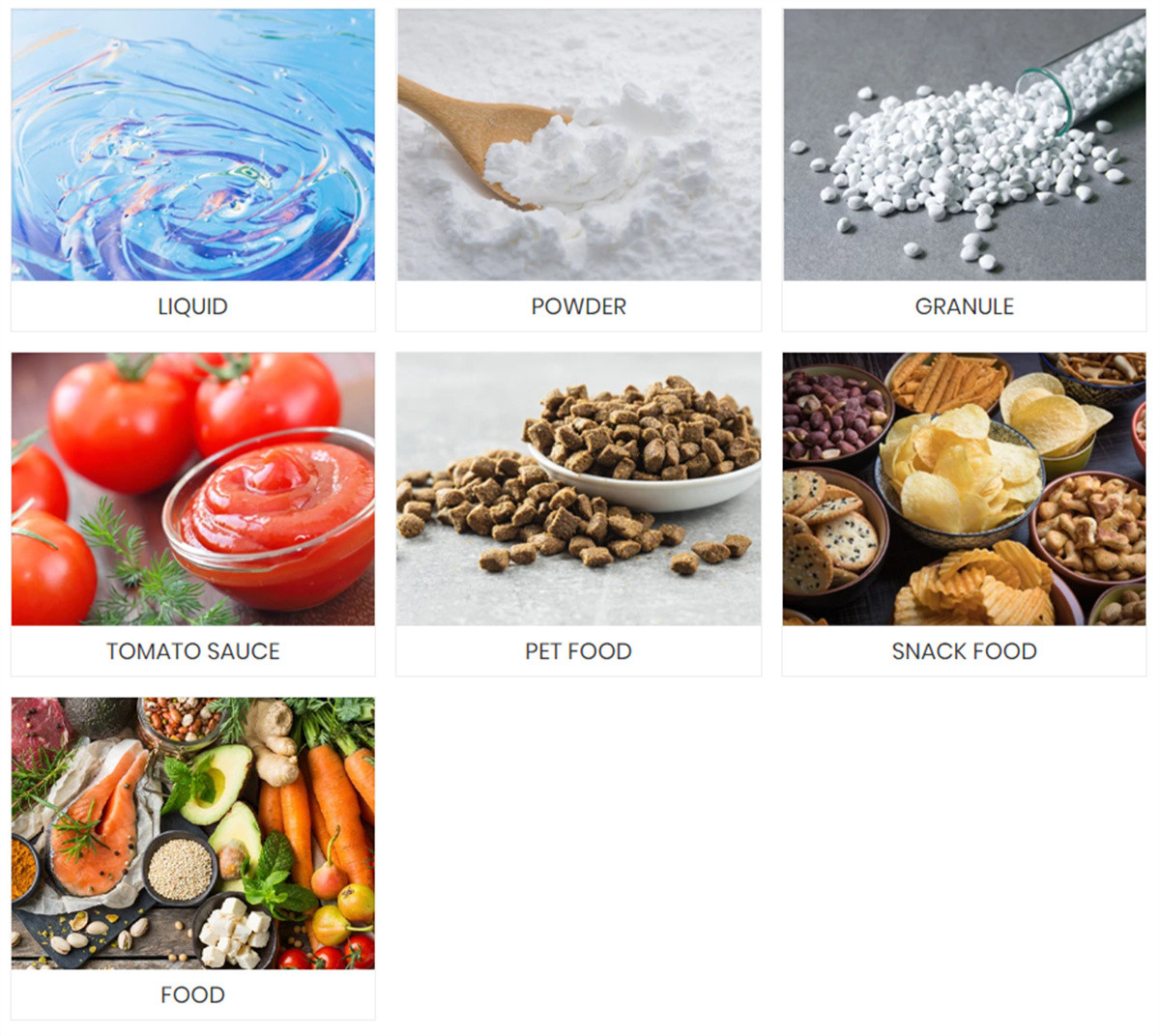

Granules, powders, liquids, sauces and other materials. |

|

Main optional configuration |

Material metering filling machine, working platform, weight selection alias, material hoist, finished product conveyor belt, metal detector. |

|

Model |

ZX8-200R |

|

Packaging Materials |

Composite bags such as stand-up bags, handbags, zipper bags, four-side seal bags, three-side seal bags, paper bags, etc. |

|

Bag size |

Width/55-200mm Length/100-400mm |

|

Fill range: |

10-2500g (depending on the type of product) |

|

Packing Speed |

45-60 packs/min |

|

Compressed air consumption |

≥0.6 cubic meters per minute (compressed air is provided by the user) |

|

Dimensions (length x width x height) |

2500×1460×1400mm |

|

Machine Weight |

1400KG |