|

Model |

ZXZK12-160 high-speed bag-feeding vacuum packaging machine |

|

Technical Highlights |

80 packs /min Bag width automatic adjustment /mechanical transmission/ Flexible conversion of feeding system / excellent waterproof performance of the whole machine |

|

Functions and Features |

The bag-feeding automatic packaging machine is composed of two rotary bodies (respectively filling system and vacuum system), and the vacuum system is a continuous rotary motion. Quickly change the packaging bag specifications, and the width of the automatic bag feeding device can be automatically adjusted at one time. It meets the hygienic standards of food processing machinery. The parts are processed with 304 stainless steel or other materials that meet food hygiene requirements to ensure food hygiene and safety. Easy to operate, using high-end electrical control system, friendly man-machine interface, easy to operate,. No blanking, no sealing, no filling bags can be recycled, no waste bags. Sealing temperature detection function, if the heating sheet is damaged, it will automatically alarm on the touch screen. The sealing method adopts the instant heating and water cooling method, so as to achieve a smoother and more beautiful sealing. The vacuum chamber is carved and milled in a computer machining center with aviation aluminum to ensure airtightness and durability |

|

Main Standard Components |

1. Bag loading system 2. PLC control system 3. Bag opening device 4. Unloading system 5. Cleaning system 6. Transfer system 7. Vacuum system 8. Vacuum split control system 9. Heat sealing control system 10. Output system 11. Vacuum chamber |

|

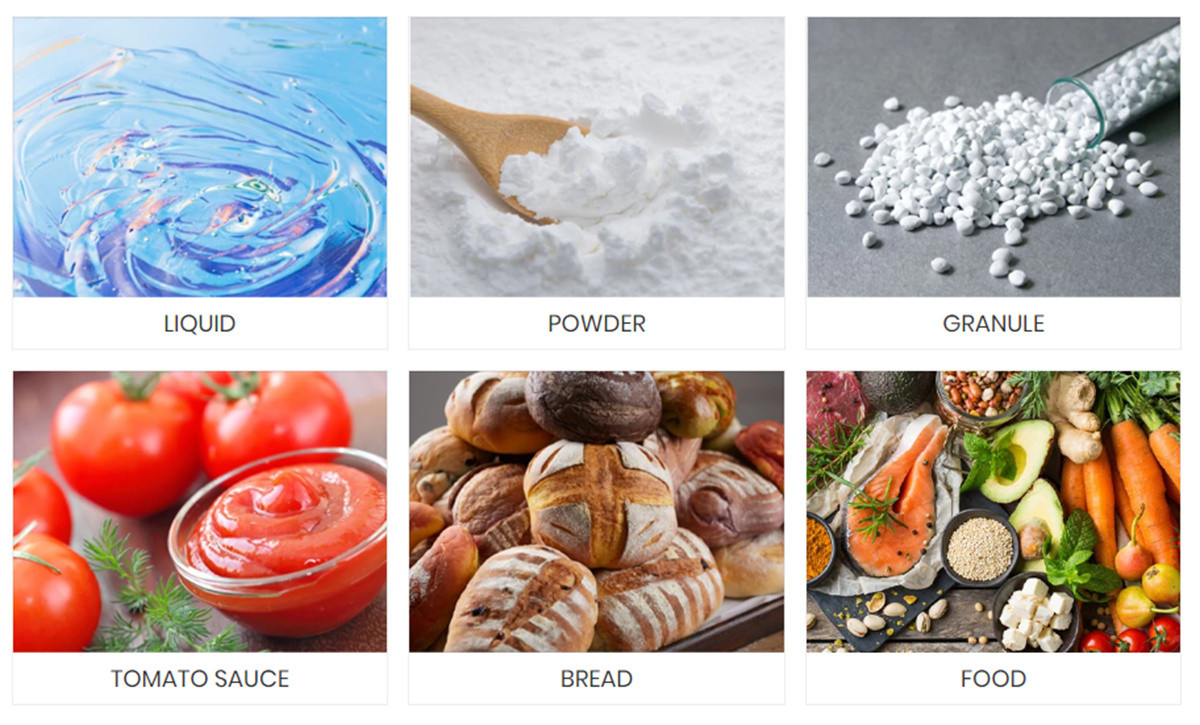

scope of application |

Various prefabricated bag products such as agricultural products, daily necessities, food, condiments, medicine, hardware, electronic products, agriculture, etc. |

|

Main optional configuration |

Material metering filling machine, working platform, weight selection alias, material hoist, finished product conveyor belt, metal detector, inkjet printer. |

|

Model |

ZXZK12-160 |

|

Packaging Materials |

Compound bags such as aluminum foil bags, four-side sealed bags, paper bags, etc. |

|

Bag size |

Width /80-160mm Length /80-240mm |

|

packing speed |

80 bags/min (the speed is determined by the product itself and the filling weight) |

|

Compressed air consumption |

≥0.6 cubic meters per minute (compressed air is provided by the user) |

|

Dimensions (length x width x height) |

2800×2150×1800mm |

|

Machine weight |

2200KG |